Bridge:

A bridge is a structure built to span physical obstacles such as a body of water, valley, or road, for the purpose of providing passage over the obstacle. There are many different designs that all serve unique purposes and apply to different situations. Designs of bridges vary depending on the function of the bridge, the nature of the terrain where the bridge is constructed and anchored, the material used to make it, and the funds available to build it.

Types of Bridges:

Bridges can be categorized in several different ways. Common categories include the type of structural elements used, by what they carry, whether they are fixed or movable, and by the materials used.

Structure type

Bridges may be classified by how the forces of tension, compression, bending, torsion and shear are distributed through their structure. Most bridges will employ all of the principal forces to some degree, but only a few will predominate. The separation of forces may be quite clear. In a suspension or cable-stayed span, the elements in tension are distinct in shape and placement. In other cases the forces may be distributed among a large number of members, as in a truss, or not clearly discernible to a casual observer as in a box beam.

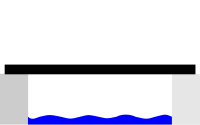

Beam bridge | Beam bridges are horizontal beams supported at each end by substructure units and can be either simply supported when the beams only connect across a single span, or continuous when the beams are connected across two or more spans. When there are multiple spans, the intermediate supports are known as piers. The earliest beam bridges were simple logs that sat across streams and similar simple structures. In modern times, beam bridges can range from small, wooden beams to large, steel boxes. The vertical force on the bridge becomes a shear and flexural load on the beam which is transferred down its length to the substructures on either side[12] They are typically made of steel, concrete or wood. Beam bridge spans rarely exceed 250 feet (76 m) long, as the flexural stresses increase proportional to the square of the length (and deflection increases proportional to the 4th power of the length).[13] However, the main span of the Rio-Niteroi Bridge, a box girder bridge, is 300 metres (980 ft).

The world's longest beam bridge is Lake Pontchartrain Causeway in southern Louisiana in the United States, at 23.83 miles (38.35 km), with individual spans of 56 feet (17 m).[14] Beam bridges are the most common bridge type in use today.

|

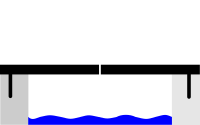

Truss bridge | A truss bridge is a bridge whose load-bearing superstructure is composed of a truss. This truss is a structure of connected elements forming triangular units. The connected elements (typically straight) may be stressed from tension, compression, or sometimes both in response to dynamic loads. Truss bridges are one of the oldest types of modern bridges. The basic types of truss bridges shown in this article have simple designs which could be easily analyzed by nineteenth and early twentieth century engineers. A truss bridge is economical to construct owing to its efficient use of materials. |

Cantilever bridge | Cantilever bridges are built using cantilevers—horizontal beams supported on only one end. Most cantilever bridges use a pair of continuous spans that extend from opposite sides of the supporting piers to meet at the center of the obstacle the bridge crosses. Cantilever bridges are constructed using much the same materials & techniques as beam bridges. The difference comes in the action of the forces through the bridge.

The largest cantilever bridge is the 549-metre (1,801 ft) Quebec Bridge in Quebec, Canada.

|

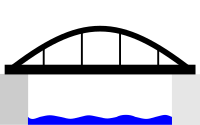

Arch bridge | Arch bridges have abutments at each end. The weight of the bridge is thrust into the abutments at either side. The earliest known arch bridges were built by the Greeks, and include the Arkadiko Bridge.

With the span of 220 metres (720 ft), the Solkan Bridge over the Soča River at Solkan in Slovenia is the second largest stone bridge in the world and the longest railroad stone bridge. It was completed in 1905. Its arch, which was constructed from over 5,000 tonnes (4,900 long tons; 5,500 short tons) of stone blocks in just 18 days, is the second largest stone arch in the world, surpassed only by the Friedensbrücke (Syratalviadukt) in Plauen, and the largest railroad stone arch. The arch of the Friedensbrücke, which was built in the same year, has the span of 90 m (300 ft) and crosses the valley of the Syrabach River. The difference between the two is that the Solkan Bridge was built from stone blocks, whereas the Friedensbrücke was built from a mixture of crushed stone and cement mortar.[15]

The world's current largest arch bridge is the Chaotianmen Bridge over the Yangtze River with a length of 1,741 m (5,712 ft) and a span of 552 metres (1,811 ft). The bridge was open April 29, 2009 in Chongqing, China.[16]

|

Tied arch bridge | Tied arch bridges have an arch-shaped superstructure, but differ from conventional arch bridges. Instead of transferring the weight of the bridge and traffic loads into thrust forces into the abutments, the ends of the arches are restrained by tension in the bottom chord of the structure. They are also called bowstring arches. |

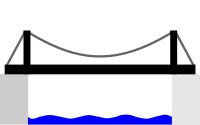

Suspension bridge | Suspension bridges are suspended from cables. The earliest suspension bridges were made of ropes or vines covered with pieces of bamboo. In modern bridges, the cables hang from towers that are attached to caissons or cofferdams. The caissons or cofferdams are implanted deep into the floor of a lake or river. Sub-types include thesimple suspension bridge, the stressed ribbon bridge, the underspanned suspension bridge, the suspended-deck suspension bridge, and the self-anchored suspension bridge.

The longest suspension bridge in the world is the 3,909 m (12,825 ft) Akashi Kaikyō Bridge in Japan.[17]

|

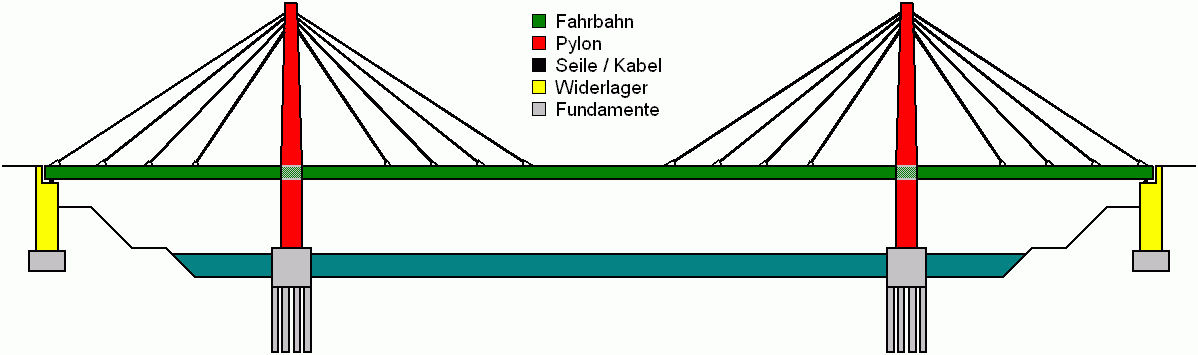

Cable-stayed bridge | Cable-stayed bridges, like suspension bridges, are held up by cables. However, in a cable-stayed bridge, less cable is required and the towers holding the cables are proportionately higher.[18] The first known cable-stayed bridge was designed in 1784 by C. T. (or C. J.) Löscher.[19][20]

The longest cable-stayed bridge is the Sutong Bridge over the Yangtze River in China.

|

Beam bridge

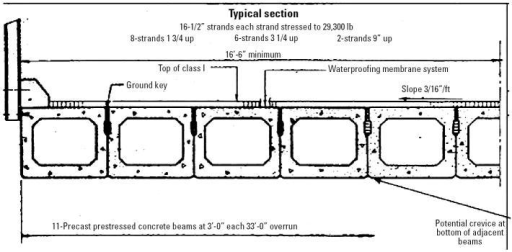

Beam bridges are the simplest structural forms for bridge spans supported by an abutment or pier at each end. No moments are transferred throughout the support, hence their structural type is known as simply supported.

The simplest beam bridge could be a stone slab or a wood plank laid across a stream. Bridges designed for modern infrastructure will usually be constructed of steel or reinforced concrete, or a combination of both. The concrete elements may be reinforced, prestressed or post-tensioned.

Types of construction could include having many beams side by side with a deck across the top of them, to a main beam either side supporting a deck between them. The main beams could be I-beams (also known as H-beams), trusses, or box girders. They could be half-through, or braced across the top to create a through bridge.

Multispan plate girder bridge deck on concrete piers.

| |

| Ancestor | Log bridge |

|---|---|

| Descendant | Box girder bridge, Plate girder bridge, trestle, truss bridge[citation needed] |

| Carries | Pedestrians, automobiles, trucks,light rail, heavy rail |

| Span range | Short |

| Material | Timber, iron, steel, reinforced concrete, prestressed concrete |

| Movable | No |

| Design effort | Low |

| Falseworkrequired | No unless cast-in-place reinforced concrete is used |

Cantilever bridge

A cantilever bridge is a bridge built using cantilevers, structures that project horizontally into space, supported on only one end. For smallfootbridges, the cantilevers may be simple beams; however, large cantilever bridges designed to handle road or rail traffic use trusses built fromstructural steel, or box girders built from prestressed concrete. The steel truss cantilever bridge was a major engineering breakthrough when first put into practice, as it can span distances of over 1,500 feet (460 m), and can be more easily constructed at difficult crossings by virtue of using little or no falsework.

|

The Pierre Pflimlin bridge is a balanced cantilever made of concrete, shown here under construction.

| |

| Ancestor | Beam bridge, Truss bridge |

|---|---|

| Related | None |

| Descendant | Swing bridge |

| Carries | Pedestrians, automobiles, trucks,light rail, heavy rail |

| Span range | Medium |

| Material | Iron, structural steel, prestressed concrete |

| Movable | No |

| Design effort | Medium |

| Falseworkrequired | |

A simple cantilever span is formed by two cantilever arms extending from opposite sides of an obstacle to be crossed, meeting at the center. In a common variant, the suspended span, the cantilever arms do not meet in the center; instead, they support a central truss bridge which rests on the ends of the cantilever arms. The suspended span may be built off-site and lifted into place, or constructed in place using special traveling supports.

Steel truss cantilevers support loads by tension of the upper members and compression of the lower ones. Commonly, the structure distributes the tension via the anchor arms to the outermost supports, while the compression is carried to the foundations beneath the central towers. Many truss cantilever bridges use pinned joints and are therefore statically determinate with no members carrying mixed loads.

Prestressed concrete balanced cantilever bridges are often built using segmental construction.

Arch Bridge

An arch bridge is a bridge with abutments at each end shaped as a curved arch. Arch bridges work by transferring the weight of the bridge and its loads partially into a horizontal thrust restrained by the abutments at either side.

Suspension Bridge:

Fig: Great Belt Bridge in Denmark, 5328 feet, year-1998

Fig: Golden Gate Bridge at San Francisco - Marin County (California) in USA , 4,200 feet, year-1937,

Fig: Brooklyn Bridge New York City (New York) in USA, 1,594 feet, year-1883

A cable-stayed bridge has one or more towers (or pylons), from which cables support the bridge deck.

Through Arch Bridge:

A through arch bridge, also known as a half-through arch bridge and through-type arch bridge, is a bridge made from materials such as steel or reinforced concrete in which the base of an arch structure is below the deck, but the top rises above it, so the deck passes through the arch. Cables or beams in tension suspend the central part of the deck from the arch.

Truss Arch Bridge:

A truss arch bridge combines the elements of the truss bridge and the arch bridge. The actual resolution of forces will depend upon the design.

Stone Arch Bridge:

The Stone Arch Bridge is a former railroad bridge crossing the Mississippi River at Saint Anthony Falls in downtown Minneapolis, Minnesota.

Address: Minneapolis, MN, United States

Construction started: 1881

Total length: 640 m

Opened: 1883

Suspension Bridge

fig: Triborough Bridge and Hell Gate in New work city, 1381 feet, year-1963

Suspension Bridge:

Suspension bridges have the longest spans of any type of bridge. Cable-stayed bridges, the next longest design, are practical for spans up to just over 1 km. Therefore the 17 longest bridges on this list are all currently the 17 longest spans of all types of vehicular bridges (other than floating pontoon bridges).

This list includes only completed suspension bridges that carry automobiles or trains. It does not include cable-stayed bridges, footbridges, or pipeline bridges.

This list includes only completed suspension bridges that carry automobiles or trains. It does not include cable-stayed bridges, footbridges, or pipeline bridges.

fig: Akashi Kaikyo Bridge in Japan 6532 feet, year-1998

fig: Xihoumen Bridge in Chaina, 5413 feet, year-2009

Fig: Great Belt Bridge in Denmark, 5328 feet, year-1998

Fig: Golden Gate Bridge at San Francisco - Marin County (California) in USA , 4,200 feet, year-1937,

Cable-Stayed Bridge

Millau viaduct

The Millau Viaduct is a cable-stayed bridge that spans the valley of the River Tarn near Millau in southern France. Wikipedia

Address: 1 Rue du Beffroi, 12100 Millau, France

Construction started: October 10, 2001

Bridge type: Cable-stayed bridge

A cable-stayed bridge has one or more towers (or pylons), from which cables support the bridge deck.

There are two major classes of cable-stayed bridges: harp and fan.

In the harp or parallel design, the cables are nearly parallel so that the height of their attachment to the tower is proportional to the distance from the tower to their mounting on the deck.

In the fan design, the cables all connect to or pass over the top of the towers. The fan design is structurally superior with minimum moment applied to the towers but for practical reasons the modified fan is preferred especially where many cables are necessary. In the modified fan arrangement the cables terminate near to the top of the tower but are spaced from each other sufficiently to allow better termination, improved environmental protection, and good access to individual cables for maintenance.

The cable-stayed bridge is optimal for spans longer than cantilever bridges, and shorter than suspension bridges. This is the range where cantilever bridges would rapidly grow heavier if the span were lengthened, and suspension bridge cabling would not be more economical if the span were shortened.

| Descendant | Side-spar cable-stayed bridge,Self-anchored suspension bridge, cantilever spar cable-stayed bridge |

|---|---|

| Carries | Pedestrians, bicycles,automobiles, trucks, light rail |

| Span range | Medium to Long |

| Material | Steel rope, post-tensioned concrete box girders, steel orconcrete pylons |

| Movable | No. |

| Design effort | medium |

| Falseworkrequired |

Comparison with suspension bridge

Cable-stayed bridges may appear to be similar to suspension bridges, but in fact they are quite different in principle and in their construction.

In suspension bridges, large main cables (normally 2) hang between the towers (normally 2), and are anchored at each end to the ground. This can be difficult to implement when ground conditions are poor. The main cables, which are free to move on bearings in the towers, bear the load of the bridge deck. Before the deck is installed, the cables are under tension from their own weight. Along the main cables smaller cables or rods connect to the bridge deck, which is lifted in sections. As this is done, the tension in the cables increases, as it does with the live load of traffic crossing the bridge. The tension on the main cables is transferred to the ground at the anchorages and by downwards tug on the towers.

- Difference between types of bridges

.jpg)

2 comments:

this was just wat i was looking for...helped me a lot

Thanks for your valuable information. It really gives me an insight on this topic. I'll visit here again for more information.

truss rental orlando

Post a Comment